How Long Does a Vehicle Wrap Last in Florida’s Climate?

Florida’s intense UV exposure, high humidity, and salt air create one of the most challenging environments for vehicle wraps in North America. While a professionally installed wrap using premium materials can last 5-7 years in moderate climates, South Florida conditions demand a more nuanced understanding of vinyl wrap longevity and the factors that determine whether your investment thrives or deteriorates prematurely.

The answer isn’t simply a timeframe—it’s about material selection, installation precision, maintenance commitment, and understanding how subtropical conditions affect different vinyl types. Here’s what actually determines vehicle wrap lifespan in the Sunshine State.

Understanding Vehicle Wrap Durability in Subtropical Conditions

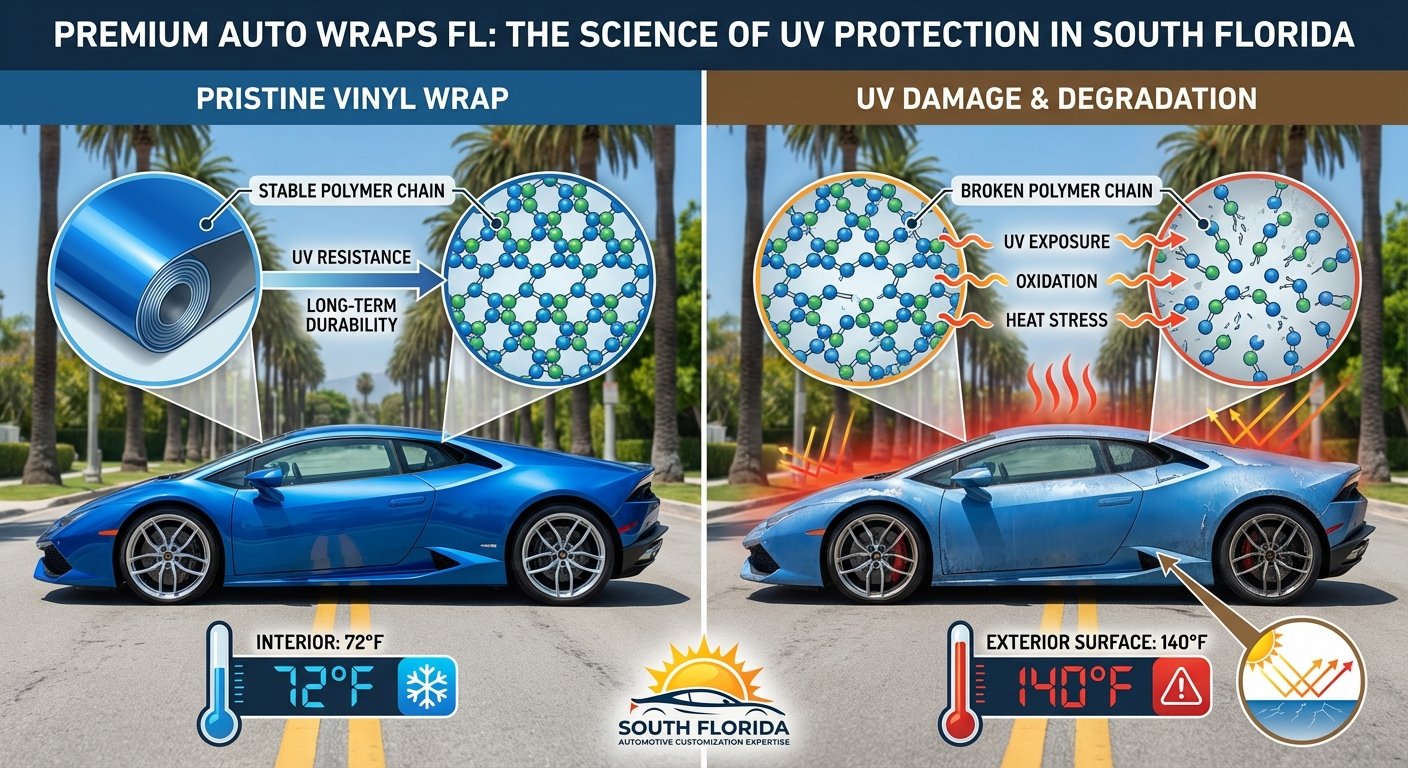

South Florida’s climate accelerates vinyl degradation through multiple mechanisms simultaneously. UV radiation breaks down polymer chains in vinyl films, while thermal cycling—dramatic temperature swings between scorching dashboards and air-conditioned interiors—creates expansion and contraction that tests adhesive bonds. Salt air corrodes edges where moisture penetrates, and humidity encourages adhesive failure if proper surface preparation wasn’t performed initially.

Premium cast vinyl wraps from manufacturers like 3M and Avery Dennison are engineered with UV inhibitors and stabilizers that provide 5-7 year warranties even in extreme conditions. However, calendared vinyl—a lower-cost alternative—typically shows degradation within 2-3 years in Florida, with color fading, adhesive failure, and edge lifting becoming apparent much sooner.

The distinction between these material grades isn’t just marketing. Cast vinyl is manufactured through a casting process that produces thin, conformable films with dimensional stability. Calendared vinyl uses rollers to create thicker, less flexible films that shrink over time. In Florida’s heat, this shrinkage accelerates dramatically, pulling away from edges and complex curves where professional installation matters most.

Material Quality: The Foundation of Wrap Longevity

3M Wrap Film Series 2080 and Avery Dennison Supreme Wrapping Film represent the professional-grade standard for vehicle wrap lifespan in challenging climates. These cast vinyl films feature dual-layer construction with UV-protective clear coats that maintain color vibrancy and gloss retention throughout their warranty period.

When discussing Florida vehicle wrap durability, the laminate layer becomes critical. Clear protective laminates add 1-2 mils of UV protection, scratch resistance, and gloss retention. This additional layer isn’t optional for South Florida applications—it’s essential insurance against accelerated degradation. Vehicles wrapped without laminate in this climate typically show fading within 18 months, even with premium base vinyl.

For marine applications, specialty films with enhanced adhesive systems handle constant moisture exposure and salt spray. Standard automotive wrap films fail quickly on boats and watercraft because their adhesive systems weren’t formulated for perpetual humidity. Marine-grade wraps use modified acrylic adhesives that maintain bonds in wet environments, extending how long car wraps last when exposed to coastal conditions.

Installation Quality: Where Longevity Is Won or Lost

Material selection provides potential longevity; installation quality determines whether that potential is realized. A $3,000 wrap using premium materials fails just as quickly as budget vinyl if surface preparation, application technique, or post-heating is compromised.

Proper surface preparation requires complete decontamination beyond simple washing. Petroleum residues, wax layers, and silicone from detailing products create barriers between vinyl adhesive and painted surfaces. Professional installers use isopropyl alcohol solutions and clay bar treatments to achieve chemically clean surfaces where adhesive bonds reach full strength.

Edge sealing and post-heating separate professional installations from amateur applications. Every cut edge, seam, and penetration point (door handles, fuel doors, mirrors) requires proper wrapping technique or sealant application to prevent moisture intrusion. Post-heating with industrial heat guns activates adhesive systems and relieves material stress—steps that amateur installers frequently skip or perform inadequately.

3M certification isn’t just credentials on a wall; it represents standardized training in application techniques specific to film types and environmental conditions. Certified installers understand how Florida humidity affects tack times, how temperature influences film stretch, and which techniques prevent the edge lifting that compromises wrap maintenance efforts months later.

The UV Factor: Florida’s Primary Wrap Degradation Mechanism

South Florida receives approximately 30% more UV radiation annually than northern states, with year-round intensity that never provides seasonal recovery periods. UV photons break chemical bonds in vinyl polymers and pigments, causing color shift, gloss reduction, and eventual material embrittlement.

Premium films incorporate UV inhibitors—chemical compounds that absorb UV energy before it reaches color pigments and polymer chains. However, these inhibitors deplete over time through a sacrificial process. Clear laminates provide additional UV protection layers, essentially doubling the protective barrier and extending vinyl wrap longevity proportionally.

Parking habits dramatically influence vehicle wrap lifespan in this UV-intensive environment. Vehicles garaged or parked in covered areas can achieve the full 7-year lifespan from premium materials. Those parked in unshaded lots year-round typically show measurable degradation by year 4, regardless of material quality. For fleet vehicles without garage access, ceramic coating applications over laminated wraps add another defensive layer against UV damage.

Maintenance Protocols That Extend Wrap Life

Proper wrap maintenance doesn’t just preserve appearance—it prevents the cumulative damage that shortens lifespan. Weekly washing removes salt deposits, pollen, and environmental contaminants that otherwise bake onto vinyl surfaces in Florida heat, creating permanent staining and surface degradation.

Hand washing with pH-neutral automotive soap remains the gold standard. Touchless car washes are acceptable alternatives, but brush-style automatic washes create micro-scratching that dulls gloss and provides entry points for moisture and UV damage. High-pressure washers require careful technique—maintaining 12-inch distance and avoiding direct spray on seams and edges prevents forced water intrusion that compromises adhesive bonds.

Wrap-safe sealants applied quarterly provide sacrificial barriers against UV exposure and environmental contaminants. Products specifically formulated for vinyl wraps—not traditional car waxes—maintain the material’s finish without petroleum distillates that degrade adhesives. This maintenance step alone can extend Florida vehicle wrap durability by 12-18 months.

Regular inspection identifies emerging issues before they become failures. Edge lifting caught early allows for targeted repair—cleaning and reheating affected areas to restore adhesion. Ignored until material pulls back several inches, the same problem requires panel replacement or complete wrap removal.

Color and Finish: Impact on Longevity

Dark colors absorb more heat, accelerating vinyl degradation in Florida’s climate. Black and deep navy wraps reach surface temperatures 30-40°F higher than white or silver equivalents parked in identical conditions. This thermal stress shortens how long car wraps last through accelerated adhesive breakdown and increased material stress.

Matte and satin finishes require more aggressive maintenance protocols than gloss films. Their textured surfaces trap contaminants more readily and show degradation more obviously. However, premium matte films from 3M or Avery perform comparably to gloss variants when properly maintained—the difference lies in visible wear patterns, not actual material breakdown.

Metallic and chrome finishes present unique challenges in South Florida. While visually striking, these films show any imperfection, contamination, or degradation immediately. Their reflective properties also intensify heat absorption in certain angles, creating localized stress points. Realistic expectations about maintenance commitment are essential with these specialty finishes.

Commercial Fleet Considerations

Fleet vehicles accumulate higher mileage and exposure hours than personal vehicles, compressing wear into shorter timeframes. A delivery van operating 10 hours daily in South Florida sun experiences more UV exposure in three years than a garaged sports car sees in seven.

For commercial applications, the calculation shifts from maximum possible lifespan to cost-per-impression and brand consistency. A wrap that maintains professional appearance for 4 years with quarterly maintenance may deliver better ROI than pushing materials to 6-year failure points with visible degradation during years 5-6.

Phased replacement strategies work well for larger fleets. Replacing 25% of wraps annually maintains consistent brand appearance across the fleet while spreading costs over multiple budget cycles. This approach also allows for design updates and messaging changes without the waste of removing wraps with remaining serviceable life.

When Replacement Makes Sense

Several indicators signal that wrap replacement delivers better value than continued maintenance. Color fading beyond 20% makes brand color matching impossible and signals UV inhibitor depletion. Edge lifting exceeding one inch, even after repair attempts, indicates adhesive system failure. Surface cracking or texture changes mean polymer breakdown has progressed beyond cosmetic concerns.

For business vehicles, brand consistency often drives replacement decisions before material failure. A three-vehicle fleet where one wrap shows noticeable degradation creates unprofessional appearance inconsistency that outweighs the cost savings of delaying replacement.

The Professional Installation Difference

The gap between professional and budget wrap longevity widens dramatically in Florida’s challenging climate. Professional installations using premium materials and proper technique routinely achieve 5-7 year lifespans with appropriate maintenance. Budget installations with lower-grade materials and compressed timelines show failure signs within 18-24 months.

This performance gap reflects material cost differences, installation time investments, and technical knowledge. Budget installers compress 40-hour installations into 16-hour timelines, eliminating the surface preparation, panel removal, and post-heating steps that determine long-term performance. The initial cost savings disappear quickly when replacement becomes necessary at the three-year mark instead of year seven.

Understanding vehicle wrap lifespan in Florida means recognizing that longevity is engineered through material selection, installation precision, and maintenance commitment. The climate doesn’t allow shortcuts—each compromised step accelerates degradation and shortens the investment return period. Premium materials installed professionally and maintained properly deliver the 5-7 year performance that justifies wrap investments for both commercial branding and personal vehicle customization.

Ready to protect your investment with a professional-grade wrap engineered for Florida’s demanding climate? Our 3M-certified installation team specializes in premium materials and techniques that maximize vinyl wrap longevity in South Florida conditions. Contact us to discuss material options, maintenance protocols, and realistic lifespan expectations for your specific application.