The difference between a premium vehicle wrap and a disappointing investment often comes down to installation quality. While a professionally installed wrap should last 5-7 years with proper care, corner-cutting can reduce that lifespan to mere months. Understanding the warning signs of subpar workmanship protects your investment and ensures your vehicle receives the treatment it deserves.

Quality wrap installation requires specialized training, proper equipment, and genuine commitment to craftsmanship. Unfortunately, the barrier to entry in the wrap industry remains relatively low, allowing inexperienced installers to compete for business without the skills necessary to deliver lasting results. Recognizing these red flags before signing a contract saves thousands in premature replacement costs and business downtime.

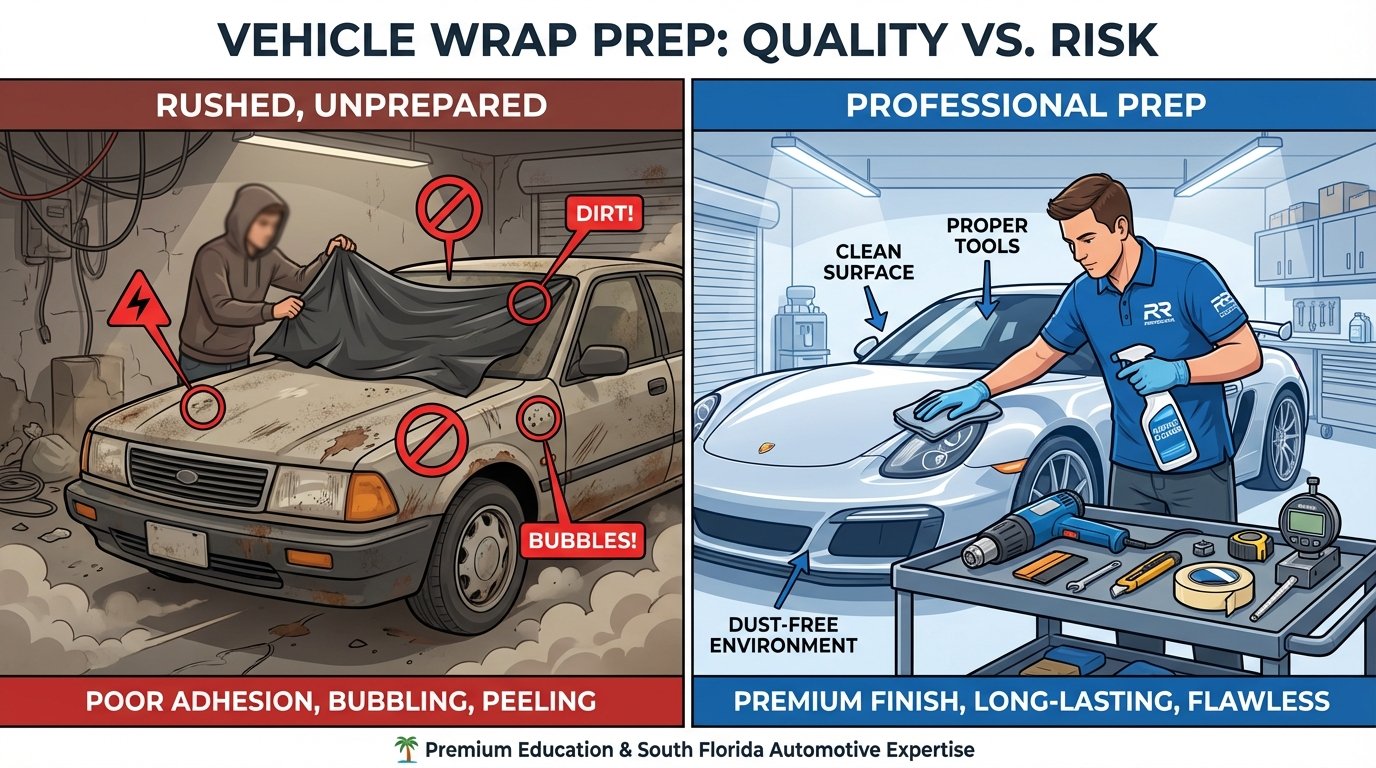

Sign #1: They Rush the Preparation Process

Professional wrap installation begins long before vinyl touches your vehicle. Surface preparation determines how well the material adheres and how long it stays in place. Installers who skip or hurry through this critical phase reveal their priorities immediately.

Proper preparation includes thorough washing, clay bar treatment to remove embedded contaminants, and complete drying. The installer should examine every inch of the surface for imperfections, existing damage, or areas requiring special attention. In South Florida’s climate, vehicles often accumulate salt residue, tree sap, and other stubborn contaminants that demand extra effort to remove completely.

A quality vehicle wrap installer allocates adequate time for this foundation work. If your installer seems eager to start applying vinyl within minutes of your vehicle’s arrival, that’s a significant warning sign. The preparation phase typically requires several hours for a full vehicle wrap, and rushing this step compromises adhesion from the start.

Watch for installers who skip the degreasing process or fail to remove badges, trim pieces, and other components that should be wrapped around rather than over. These shortcuts create lift points where the vinyl will eventually peel, dramatically reducing the wrap’s lifespan.

Sign #2: They Don’t Discuss Material Options or Quality Differences

Premium wrap service providers educate clients about material choices because they understand how dramatically quality affects outcomes. Not all vinyl films are created equal, and installers committed to excellence want customers to understand what they’re purchasing.

Professional installers typically work with top-tier manufacturers like 3M, Avery Dennison, or Orafol. These materials feature superior conformability, UV resistance, and adhesive technology. They’re engineered to withstand South Florida’s intense sun exposure and temperature fluctuations without fading or failing prematurely.

If your installer doesn’t mention brand names, warranty coverage, or material specifications, they may be using inferior products to increase profit margins. Budget materials might cost 40-50% less than premium alternatives, but they deliver proportionally diminished results.

Ask specific questions about the vinyl being used. A knowledgeable installer should explain the differences between cast and calendared vinyl, discuss why cast films are preferable for complex curves and long-term applications, and provide manufacturer warranty documentation. Vague or evasive answers suggest the installer prioritizes profit over performance.

Sign #3: The Facility Isn’t Climate-Controlled and Clean

Installation environment dramatically impacts wrap quality. Professional wrap installation requires a clean, climate-controlled space that protects the vehicle and materials throughout the process.

Dust particles, debris, and insects become permanently trapped under vinyl if they land on adhesive surfaces during installation. Once sealed, these contaminants create visible imperfections that can’t be corrected without removing and replacing the affected panels. In South Florida’s humidity, temperature control becomes equally critical for proper adhesion and material workability.

Visit the installation facility before committing. Professional shops feature sealed bays with filtered air systems, proper lighting for detecting imperfections, and climate control maintaining temperatures between 68-77°F with controlled humidity levels. The workspace should appear organized and meticulously maintained.

Installing wraps outdoors or in open garages exposes your vehicle to countless variables that compromise results. While emergency mobile repairs might occasionally occur in less-than-ideal conditions, complete vehicle wraps demand controlled environments. Installers working in suboptimal facilities either don’t understand quality standards or choose to ignore them.

Sign #4: They Avoid Discussing Warranties or Guarantees

Confidence in workmanship shows through warranty offerings. Installers who stand behind their work provide clear, written guarantees covering both materials and installation labor.

Quality wrap installations typically include manufacturer material warranties (often 5-7 years against fading and adhesive failure) plus installer workmanship guarantees covering issues like lifting, bubbling, and premature failure due to installation errors. Professional installers maintain 3M Preferred Installer status or equivalent certifications from major manufacturers, which requires meeting strict quality standards and provides enhanced warranty coverage.

Be wary of installers who offer only verbal assurances or warranties significantly shorter than industry standards. A 90-day warranty on installation workmanship suggests the installer expects problems. Many wrap installation mistakes manifest within the first few weeks as adhesive bonds stabilize and environmental factors stress improperly installed areas.

Review warranty documentation carefully. Professional installers provide detailed terms explaining what’s covered, exclusion criteria, and the process for addressing warranty claims. Reluctance to provide written guarantees indicates lack of confidence in the installation quality.

Sign #5: Their Portfolio Shows Visible Flaws

Every installer showcases their best work in portfolios and social media. If you spot imperfections in their highlight reel, imagine what their average installations look like.

Examine portfolio images critically for signs of poor workmanship: visible seams where none should exist, inconsistent panel gaps, wrinkled or stretched material around curves, and misaligned patterns or graphics. Professional installers create nearly invisible seams in strategic locations, maintain factory-like panel gaps, and achieve smooth, tension-free application even on complex curves.

Pay attention to detail shots. Can you see the edges where vinyl meets body panels? They should be precisely tucked and sealed, not obviously trimmed and left exposed. Do color-change wraps look like factory paint, or can you tell it’s vinyl? Premium installations on luxury vehicles demand perfection that passes casual inspection.

Request references from recent clients with similar vehicles or applications. Speaking with previous customers reveals insights about the installer’s professionalism, problem-resolution approach, and how the wrap has held up over time. Installers who hesitate to provide references may be hiding dissatisfied customers.

Sign #6: They Quote Suspiciously Low Prices

Professional wrap installation requires substantial investment in materials, training, equipment, and facility overhead. Pricing significantly below market rates indicates compromises somewhere in the process.

Understanding approximate costs helps identify unrealistic quotes. Full vehicle color changes using premium materials and professional installation typically range from $3,500-$6,000 for standard vehicles, with luxury and exotic cars commanding higher prices due to complexity. Partial wraps, fleet graphics, and commercial applications vary based on coverage and design complexity.

Installers offering full wraps for $1,500-$2,000 can’t possibly use premium materials and allocate appropriate labor time while maintaining a viable business. They’re either using inferior materials, rushing the installation, skipping critical preparation steps, or all three. The temporary savings become expensive when the wrap fails prematurely and requires complete replacement.

Quality-focused installers price services based on the time required to execute proper techniques and the materials necessary to deliver lasting results. While prices should be competitive within the professional market, choosing wrap installer based solely on the lowest bid almost always leads to disappointment.

Sign #7: They Lack Relevant Certifications and Training

Professional wrap installation demands specialized skills developed through formal training and ongoing education. Legitimate installers invest in certification programs that verify their competency and keep them current with evolving techniques and materials.

3M Preferred Installer certification represents one of the industry’s most recognized credentials. Achieving this status requires completing manufacturer training, demonstrating installation proficiency, maintaining appropriate insurance coverage, and meeting ongoing quality standards. Similar programs exist through Avery Dennison and other major manufacturers.

Certified installers receive early access to new products, technical support from manufacturers, and enhanced warranty offerings that protect customers. They also participate in continuing education that refines techniques and introduces innovations in materials and application methods.

Ask potential installers about their training background, certifications, and how long they’ve been installing wraps professionally. While everyone starts somewhere, your luxury vehicle or commercial fleet shouldn’t serve as practice material for inexperienced installers learning on the job.

Why Corner-Cutting Matters More Than You Think

The consequences of poor installation extend far beyond aesthetics. Improperly installed wraps can damage vehicle paint during removal, void manufacturer warranties, and create safety issues if vinyl obstructs visibility or interferes with sensors and cameras.

For commercial fleets, premature wrap failure means vehicles return to the shop for replacement sooner than planned, multiplying costs and reducing the return on your branding investment. Fleet downtime for re-wrapping affects operations and productivity.

South Florida’s environmental conditions amplify installation mistakes. Intense UV exposure, salt air for coastal vehicles, and temperature extremes stress every aspect of the wrap. Minor adhesion issues that might take years to manifest in temperate climates can fail within months under these demanding conditions. Only professional wrap installation using premium materials withstands these challenges consistently.

What Professional Installation Looks Like

Understanding quality standards helps recognize excellence when you see it. Professional installers take pride in details that separate exceptional work from merely adequate results.

Expect the installation process to take several days for a complete vehicle wrap. Full-size vehicles typically require 2-4 days of careful work, with complex luxury cars demanding even more time. Installers who promise overnight turnarounds can’t possibly allocate adequate attention to preparation, application, and quality control.

Throughout installation, professionals maintain open communication about progress, explain any challenges discovered, and discuss solutions before proceeding. They welcome clients checking progress and asking questions because they’re confident in their work.

Upon completion, professional installers review care and maintenance requirements, provide detailed warranty documentation, and schedule follow-up inspections to ensure the wrap is performing as expected. This ongoing relationship reflects commitment to customer satisfaction beyond the initial sale.

Making the Right Choice

Your vehicle deserves professional treatment from installers who respect the craft and prioritize quality. The seven warning signs outlined here provide a framework for evaluating potential installers and protecting your investment.

Don’t let impressive marketing or rock-bottom pricing override your judgment. Visit facilities, examine previous work, verify certifications, and trust your instincts. Professional installers demonstrate their expertise through every interaction, from initial consultation through final delivery.

When you’re ready to invest in a quality vehicle wrap installed by certified professionals who understand what excellence requires, contactWrapsGurus. Our team’s commitment to premium materials, proven techniques, and customer satisfaction ensures your vehicle receives the attention it deserves. We don’t cut corners because we know it matters.