A commercial fleet represents one of your business’s most visible marketing assets. Every delivery, service call, or client meeting puts your brand on wheels, generating thousands of daily impressions. When deciding between fleet wrapping and traditional paint for commercial vehicles, most business owners focus solely on upfront costs. However, the true financial picture requires examining total lifecycle expenses, downtime impacts, and return on investment over a five-year period.

The choice between vehicle wrap vs paint extends far beyond initial price tags. Smart business owners calculate fleet graphics ROI by considering maintenance requirements, resale value protection, flexibility for rebranding, and the hidden costs of vehicle downtime during application and repair.

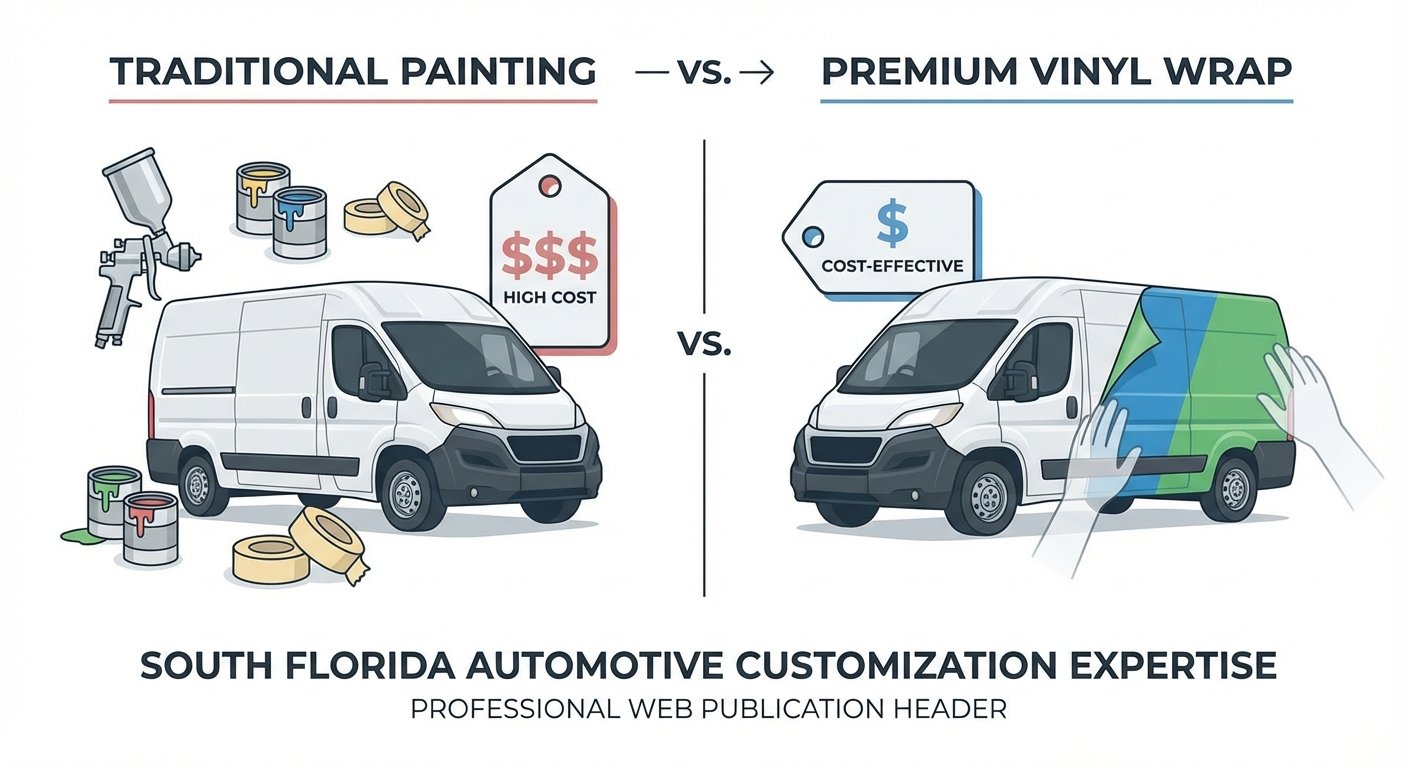

Initial Investment Comparison

Understanding the upfront costs provides a starting point for financial analysis. Traditional paint and professional vinyl wraps occupy different price ranges, but these numbers tell only part of the story.

Traditional Fleet Paint Costs

A professional paint job for a commercial cargo van typically ranges from $3,000 to $8,000 per vehicle, depending on color complexity and finish quality. Fleet painting requires extensive preparation including sanding, priming, multiple base coats, and clear coat application. Custom logos and graphics add $500 to $2,000 per vehicle, with complex designs commanding premium pricing.

The process demands removing or masking components like mirrors, lights, and trim pieces. Professional paint shops often quote 5-7 business days per vehicle for complete fleet painting, creating significant operational challenges for businesses that need vehicles on the road.

Professional Fleet Wrapping Investment

Fleet wrapping cost for a full commercial van wrap ranges from $2,500 to $5,000 when using premium materials like 3M or Avery Dennison films. Partial wraps covering high-visibility areas cost $1,200 to $2,500 per vehicle, offering budget-conscious alternatives without sacrificing brand impact.

Professional installation by 3M-certified technicians ensures proper adhesion and longevity. The process typically requires 1-3 days per vehicle, significantly reducing downtime compared to paint. Business vehicle wraps include unlimited graphic complexity within the base price—intricate logos, photographic images, and detailed designs cost no more to print than simple text.

Downtime: The Hidden Cost Factor

Vehicle downtime directly impacts revenue generation, particularly for service businesses where each van represents a revenue stream. This often-overlooked factor dramatically affects total cost calculations.

Traditional painting requires 5-7 business days per vehicle. A service company operating 10 vans faces 50-70 total days of lost revenue potential. If each van generates $500 daily in billable work, that’s $25,000 to $35,000 in opportunity cost during the painting process alone.

Fleet wrapping reduces downtime to 1-3 days per vehicle, cutting opportunity costs by 60-80%. The installation process doesn’t require extensive disassembly, and wrap shops can often work around business schedules. For a 10-vehicle fleet, that translates to only 10-30 days of combined downtime—a difference of 40 revenue-generating days compared to paint.

Smart fleet managers stagger wrap installations, keeping most vehicles operational while rotating units through the shop. This approach proves nearly impossible with paint due to extended timelines.

Durability and Maintenance Expenses

Long-term maintenance costs significantly impact total ownership expenses. The South Florida environment—with intense UV exposure, salt air near coastal areas, and frequent rain—tests both paint and wraps.

Paint Maintenance Reality

Traditional paint requires regular maintenance to preserve appearance. Commercial vehicles face chips, scratches, and oxidation from daily use. Minor damage repair costs $150-400 per incident, with color-matching challenges complicating touch-ups on older vehicles.

Fleet paint fades over time, particularly on horizontal surfaces like hoods and roofs exposed to relentless Florida sun. Within three years, noticeable color variation often appears between repaired sections and original paint. Complete repainting becomes necessary every 5-7 years to maintain professional appearance.

Painted graphics deteriorate even faster. Vinyl decals applied over paint typically last 3-5 years before peeling, fading, or cracking. Removing and replacing these graphics costs $300-800 per vehicle.

Wrap Maintenance Advantages

Premium vinyl wraps using 3M IJ180Cv3 with 8548G laminate provide 7-9 years of durability when professionally maintained. These cast vinyl films resist fading, with minimal color shift even under intense UV exposure. The laminate layer protects against scratches, bird droppings, and chemical exposure.

Damage repair proves remarkably cost-effective with wraps. A damaged panel can be reprinted and replaced for $200-500 without affecting surrounding areas. No color-matching concerns exist since digital files ensure perfect reproduction.

Routine wrap maintenance involves regular washing with pH-neutral soap—the same cleaning protocol used for painted vehicles. No special treatments, waxing, or protective coatings are required, simplifying fleet care.

Flexibility and Rebranding Costs

Business needs evolve. Companies rebrand, phone numbers change, websites update, and promotional campaigns require fresh messaging. The cost of adapting your fleet to these changes varies dramatically between paint and wraps.

Repainting an entire fleet for rebranding costs essentially the same as the initial paint job—$3,000 to $8,000 per vehicle plus downtime. Businesses face this full expense whenever brand updates occur.

Fleet wrapping provides unmatched flexibility. Wraps remove cleanly without damaging underlying paint, and new wraps install for the same cost as originals. Partial updates—changing contact information or adding promotional messaging—cost $300-800 per vehicle by replacing specific panels rather than rewrapping entirely.

This flexibility delivers tangible value. A real estate company can update hundreds of agent phone numbers across their fleet for under $5,000 total, a project that would cost $30,000+ with painted graphics. Commercial fleet branding that adapts to market conditions provides competitive advantages that rigid paint solutions cannot match.

Resale Value Protection

Fleet vehicles eventually require replacement. The condition of underlying paint significantly impacts resale values, trade-in amounts, and lease return charges.

Traditional paint endures environmental damage throughout vehicle life. Stone chips, scratches, and UV degradation reduce resale appeal. Commercial vehicles with custom paint colors face additional challenges—buyers prefer standard colors, and unique branding schemes can detract from value.

Vehicle wraps protect original factory paint from UV exposure, minor impacts, and environmental contaminants. When removed, the underlying paint often looks showroom-fresh, commanding premium resale prices. White fleet vehicles wrapped for 5-7 years can sell for $1,500-3,000 more than equivalent painted vehicles showing wear.

For leased fleet vehicles, this factor becomes even more critical. Lease return inspections charge hefty fees for paint damage, scratches, and excessive wear. Wrapped vehicles avoid these penalties entirely, with the wrap removed before return to reveal protected factory finish.

Calculating the Protection Premium

A 10-vehicle fleet upgraded every six years benefits from approximately $15,000-30,000 in additional resale value thanks to paint protection from wraps. This recovered value directly offsets initial wrap investment, improving overall fleet graphics ROI substantially.

Marketing Impact and Brand Consistency

The financial analysis must include marketing effectiveness. Fleet graphics serve as mobile billboards, generating brand impressions that traditional advertising cannot match.

Professional wraps deliver vibrant, photographically accurate graphics impossible with paint. The color gamut of digital printing exceeds paint capabilities, creating eye-catching designs that capture attention in traffic. Metallic finishes, color-shift effects, and textured laminates add dimension that flat paint cannot replicate.

Brand consistency across fleets proves easier with wraps. Each vehicle receives graphics printed from identical digital files, ensuring perfect color matching and design accuracy. Paint introduces variables—different painters, batch variations, and color-matching challenges—that create inconsistency across large fleets.

This consistency extends beyond aesthetics. Professional appearance builds customer trust. A cohesive, well-maintained fleet suggests operational excellence and attention to detail. Faded, mismatched, or damaged graphics send opposite messages, potentially costing contracts and customer confidence.

Five-Year Total Cost Analysis

Examining complete five-year costs reveals the true financial picture. Consider a 10-vehicle cargo van fleet operating in a service business context:

Traditional Paint Scenario

- Initial painting: $60,000 (10 vehicles at $6,000 average)

- Downtime opportunity cost: $30,000 (60 days at $500 per day)

- Touch-up repairs: $8,000 (averaging two incidents per vehicle over five years)

- Decal replacement: $5,000 (partial graphic updates)

- Reduced resale value: $15,000 (paint wear and damage)

- Five-year total: $118,000

Professional Fleet Wrapping Scenario

- Initial wrapping: $40,000 (10 vehicles at $4,000 average)

- Downtime opportunity cost: $10,000 (20 days at $500 per day)

- Minor repairs: $3,000 (panel replacements as needed)

- Information updates: $3,000 (partial panel replacements)

- Resale value premium: -$20,000 (protected paint adds value)

- Five-year total: $36,000

The fleet wrapping approach saves $82,000 over five years while delivering superior graphics quality, easier updates, and enhanced flexibility. These numbers become even more compelling for larger fleets or businesses requiring frequent rebranding.

South Florida Considerations

Operating fleets in South Florida introduces specific challenges that affect both paint and wrap performance. UV exposure here ranks among the nation’s highest, accelerating degradation of unprotected finishes.

Premium wrap materials specifically engineered for harsh conditions—like 3M’s Envision series or Avery Dennison’s Supreme Wrapping Film—include UV inhibitors that maintain color stability under intense sun exposure. The protective laminate shields graphics from salt air, a consideration for businesses operating near coastal areas.

Paint faces accelerated oxidation in this environment. The combination of UV radiation, heat, and salt creates conditions that fade and damage painted surfaces faster than in moderate climates. This reality shortens the effective lifespan of fleet paint in South Florida, potentially requiring repainting on 4-5 year cycles rather than the 6-7 years possible in less demanding environments.

Making the Strategic Choice

The financial analysis clearly favors professional fleet wrapping for most commercial applications. Lower initial costs, reduced downtime, easier maintenance, rebranding flexibility, and resale value protection create compelling economic advantages over traditional paint.

However, the decision requires considering your specific circumstances. Businesses planning minimal branding changes over long periods might find paint acceptable, particularly for smaller fleets where downtime doesn’t significantly impact operations. Classic vehicle collectors or specialty applications where paint authenticity matters represent valid exceptions to wrap recommendations.

For growing businesses, companies with evolving branding, and organizations prioritizing marketing impact, fleet wrapping delivers superior return on investment. The combination of lower total cost, enhanced flexibility, and professional appearance makes wraps the strategic choice for commercial fleet branding.

Quality matters tremendously in wrap outcomes. 3M-certified installers using premium materials deliver wraps that meet manufacturer warranty requirements and perform as projected in cost analyses. Budget wrap services using inferior materials and inexperienced installers create false economies—wraps that fail prematurely, require extensive repairs, and ultimately cost more than professional installation.

Transform your commercial fleet into a mobile marketing powerhouse while protecting your investment and reducing total lifecycle costs. Professional fleet wrapping delivers measurable ROI through lower expenses, reduced downtime, and enhanced brand visibility. Contact our team to discuss your specific fleet requirements and receive a detailed cost analysis comparing wrap and paint options for your business. Let’s create a fleet branding solution that drives both marketing results and financial performance.